|

本标准等效采用国际标准ISO6162《液压分体法兰》与美国机动工程师协会标准SAEJ518和德国西马克公司标准SN532,其尺寸可以互换。

|

|

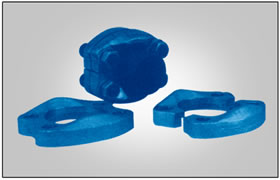

1、A型--附接法兰的型式和尺寸(见图1表1)

|

|

|

|

|

表1

| 公称通径 |

工作压力

MPa max |

Do

max |

d

max |

A |

T |

L |

M |

螺钉

GB70(8.8) |

O型密封圈GB3451.1 |

| mm |

in |

|

3000PSI法兰 |

| 15 |

1/2 |

21 |

20 |

14 |

17.5 |

38.1 |

30 |

24.3 |

M8×25 |

19×3.55 |

| 20 |

3/4 |

21 |

30 |

20 |

22.3 |

47.6 |

35 |

32.2 |

M10×30 |

25×3.55 |

| 25 |

1 |

21 |

38 |

28 |

26.2 |

52.4 |

40 |

38.5 |

M10×30 |

32.5×3.55 |

| 32 |

11/4 |

21 |

42 |

33 |

30.2 |

58.7 |

45 |

43.7 |

M10×35 |

37.5×3.55 |

| 40 |

11/2 |

21 |

48 |

42 |

35.7 |

69.9 |

50 |

50.8 |

M12×35 |

47.5×3.55 |

| 50 |

2 |

21 |

60 |

52 |

42.9 |

77.8 |

60 |

62.8 |

M12×35 |

56×3.55 |

| 65 |

21/2 |

17.5 |

76 |

65 |

50.8 |

88.9 |

70 |

74.9 |

M12×40 |

69×3.55 |

| 80 |

3 |

14 |

89 |

81 |

61.9 |

106.4 |

80 |

90.9 |

M16×45 |

85×3.55 |

| 100 |

4 |

3.5 |

114 |

106 |

77.8 |

130.2 |

80 |

115 |

M16×50 |

112×3.55 |

| 125 |

5 |

3.5 |

140 |

132 |

92.1 |

152.4 |

80 |

140.5 |

M16×55 |

136×3.55 |

|

6000PSI法兰 |

| 15 |

1/2 |

41 |

20 |

14 |

18.2 |

40.5 |

40 |

24.6 |

M8×30 |

19×3.55 |

| 20 |

3/4 |

41 |

30 |

20 |

23.8 |

50.8 |

45 |

32.5 |

M10×35 |

25×3.55 |

| 25 |

1 |

41 |

38 |

28 |

27.8 |

57.2 |

50 |

38.8 |

M12×40 |

32.5×3.55 |

| 32 |

11/4 |

41 |

42 |

33 |

31.8 |

66.7 |

55 |

44.5 |

M14×45 |

37.5×3.55 |

| 40 |

11/2 |

41 |

48 |

42 |

36.5 |

79.4 |

60 |

51.6 |

M16×50 |

47.5×3.55 |

| 50 |

2 |

41 |

60 |

52 |

44.5 |

96.8 |

70 |

67.6 |

M20×60 |

56×3.55 |

| 65 |

21/2 |

32 |

89 |

65 |

58.7 |

123.8 |

75 |

89.5 |

M24×8 |

69×3.55 |

| 80 |

3 |

32 |

114 |

81 |

71.4 |

152.4 |

80 |

114.5 |

M30×100 |

85×3.55 |

|

2、B型--连接法兰的型式和尺寸(见图2和表2)

|

|

|

表2

| 公称通径 |

工作压力

MPa max |

Do

max |

d

max |

A |

T |

L |

M |

螺母

GB6170 |

螺钉

GB70(8.8) |

O型密封圈GB3451.1 |

| mm |

in |

|

3000PSI法兰 |

| 15 |

1/2 |

21 |

20 |

14 |

17.5 |

38.1 |

60 |

24.3 |

M8 |

M8×40 |

19×3.55 |

| 20 |

3/4 |

21 |

30 |

20 |

22.3 |

47.6 |

70 |

32.2 |

M10 |

M10×40 |

25×3.55 |

| 25 |

1 |

21 |

38 |

28 |

26.2 |

52.4 |

80 |

39.5 |

M10 |

M10×45 |

32.5×3.55 |

| 32 |

11/4 |

21 |

42 |

33 |

30.2 |

58.7 |

90 |

43.7 |

M10 |

M10×45 |

37.5×3.55 |

| 40 |

11/2 |

21 |

48 |

42 |

35.7 |

69.9 |

100 |

50.8 |

M12 |

M12×50 |

47.5×3.55 |

| 50 |

2 |

21 |

60 |

52 |

42.9 |

77.8 |

120 |

62.8 |

M12 |

M12×50 |

56×3.55 |

| 65 |

21/2 |

17.5 |

76 |

65 |

50.8 |

88.9 |

140 |

74.9 |

M16 |

M16×60 |

69×3.55 |

| 80 |

3 |

14 |

89 |

81 |

61.9 |

106.4 |

160 |

90.9 |

M16 |

M16×70 |

85×3.55 |

| 100 |

4 |

3.5 |

114 |

106 |

77.8 |

130.2 |

160 |

115 |

M16 |

M16×80 |

112×3.55 |

| 125 |

5 |

3.5 |

140 |

132 |

92.1 |

152.4 |

160 |

140.5 |

M16 |

M16×80 |

136×3.55 |

|

6000PSI法兰 |

| 15 |

1/2 |

41 |

20 |

14 |

18.2 |

40.5 |

80 |

24.6 |

M8 |

M8×45 |

19×3.55 |

| 20 |

3/4 |

41 |

30 |

20 |

23.8 |

50.8 |

90 |

32.5 |

M10 |

M10×50 |

25×3.55 |

| 25 |

1 |

41 |

38 |

28 |

27.8 |

57.2 |

100 |

38.8 |

M12 |

M12×65 |

32.5×3.55 |

| 32 |

11/4 |

41 |

42 |

33 |

31.8 |

66.7 |

110 |

44.5 |

M14 |

M14×70 |

37.5×3.55 |

| 40 |

11/2 |

41 |

48 |

42 |

36.5 |

79.4 |

120 |

51.6 |

M16 |

M16×80 |

47.5×3.55 |

| 50 |

2 |

41 |

60 |

52 |

44.5 |

96.8 |

140 |

67.6 |

M20 |

M20×100 |

56×3.55 |

| 65 |

21/2 |

32 |

89 |

65 |

58.7 |

123.8 |

150 |

89.5 |

M24 |

M24×120 |

69×3.55 |

| 80 |

3 |

32 |

114 |

81 |

71.4 |

152.4 |

160 |

114.5 |

M30 |

M30×140 |

85×3.55 |

|

3、其它连接型式见图3~图6,相关尺寸见表1和表2。 |

|

|

|

|

|

|

图3 C型--不带接管的

连接法兰 |

图4 D型--带法兰盖的

连接法兰 |

图5 E型--带法兰的

附接法兰 |

图6 F型--不带接管的

附接法兰 |

法兰尺寸见图7和表3 |

|

|

表3

公称通径

DN |

工作压力

MPa |

A |

T |

M |

L1 |

L3 |

L4 |

L5 |

L6 |

L7 |

d1 |

d2 |

R |

|

3000PSI法兰 |

| 15 |

21 |

17.5 |

38.1 |

24.3 |

54 |

22 |

8 |

19 |

13 |

6.2 |

9 |

31 |

8 |

| 20 |

21 |

22.3 |

47.6 |

32.2 |

65 |

25 |

10 |

22 |

14 |

6.2 |

11 |

38.9 |

9 |

| 25 |

21 |

26.2 |

52.4 |

38.5 |

70 |

28.5 |

12 |

22 |

14 |

7.5 |

11 |

45.3 |

9 |

| 32 |

21 |

30.2 |

58.7 |

43.7 |

80 |

35.5 |

14 |

24 |

16 |

7.5 |

11 |

51.6 |

10 |

| 40 |

21 |

35.7 |

69.9 |

50.8 |

94 |

40.5 |

17 |

25 |

16 |

7.5 |

13.5 |

61.1 |

12 |

| 50 |

21 |

42.9 |

77.8 |

62.8 |

102 |

47.5 |

20.5 |

26 |

16 |

9 |

13.5 |

72.3 |

12 |

| 65 |

17.5 |

50.8 |

88.9 |

76.9 |

115 |

49.5 |

24.5 |

38 |

19 |

9 |

13.5 |

84.9 |

13 |

| 80 |

14 |

61.9 |

106.4 |

90.9 |

135 |

64.5 |

30 |

41 |

21 |

9 |

17.5 |

102.4 |

14 |

| 100 |

3.5 |

77.8 |

130.2 |

115 |

163 |

72.5 |

38 |

35 |

24 |

10.7 |

17.5 |

127.8 |

16 |

| 125 |

3.5 |

92.1 |

152.4 |

140.5 |

184 |

81.5 |

45 |

41 |

30 |

10.7 |

17.5 |

153.2 |

16 |

|

6000PSI法兰 |

| 15 |

41 |

18.2 |

40.5 |

24.6 |

56 |

23 |

8 |

22 |

16 |

7.2 |

9 |

32.5 |

8 |

| 20 |

41 |

23.8 |

50.8 |

32.5 |

71 |

29 |

11 |

28 |

19 |

8.2 |

11 |

42 |

10 |

| 25 |

41 |

27.8 |

57.2 |

38.8 |

81 |

34 |

13 |

33 |

24 |

9.0 |

13.5 |

48.4 |

12 |

| 32 |

41 |

31.8 |

66.7 |

44.5 |

95 |

38 |

15 |

38 |

27 |

9.8 |

15.5 |

54.8 |

14 |

| 40 |

41 |

36.5 |

79.4 |

51.6 |

113 |

46.5 |

17 |

43 |

30 |

12.0 |

17.5 |

64.3 |

17 |

| 50 |

41 |

44.5 |

96.8 |

67.6 |

133 |

56 |

21 |

52 |

37 |

12.0 |

22 |

80.2 |

18 |

| 65 |

32 |

58.7 |

123.8 |

89.5 |

175 |

74 |

28 |

- |

45 |

20.0 |

26 |

108.5 |

25 |

| 80 |

32 |

71.4 |

152.4 |

114.5 |

215 |

88 |

35 |

- |

55 |

25.0 |

32 |

132.5 |

31 |

|

焊接头和法兰盖的型式和尺寸见图8~图10和表4 |

|

|

|

|

|

图8 不带O型密封圈的焊接头 |

图9 带O型密封圈的焊接接头 |

图10 带O型密封圈的法兰盖 |

表4

公称通径

DN |

工作压力

MPa |

d1 |

d2 |

d3

max |

L1 |

L2 |

L3 |

推荐管子尺寸 |

(A)

d4×S |

(B)

d4×S |

|

3000PSI法兰 |

| 15 |

21 |

30.1 |

24 |

14 |

30 |

13 |

6.8 |

20×2.5 |

20×30 |

| 20 |

21 |

38.1 |

31.5 |

20 |

35 |

14 |

6.8 |

25×3.0 |

25×3.0 |

| 25 |

21 |

44.4 |

38 |

28 |

40 |

14 |

8 |

30×3.0 |

30×4.0 |

| 32 |

21 |

50.8 |

43 |

33 |

45 |

16 |

8 |

38×3.0 |

38×4.0 |

| 40 |

21 |

60.3 |

50 |

42 |

50 |

16 |

8 |

48×2.6 |

48×5.0 |

| 50 |

21 |

71.0 |

62 |

52 |

60 |

16 |

9.6 |

60×2.9 |

60×5.6 |

| 65 |

17.5 |

84.1 |

74.5 |

65 |

70 |

19 |

9.6 |

76×2.9 |

76×7.0 |

| 80 |

14 |

101.6 |

89 |

81 |

80 |

21 |

9.6 |

89×3.2 |

89×3.6 |

| 100 |

3.5 |

127 |

114 |

106 |

80 |

24 |

11.3 |

114×3.6 |

114×3.6 |

| 125 |

3.5 |

152.4 |

140 |

132 |

80 |

30 |

11.3 |

140×4.0 |

140×3.6 |

|

6000PSI法兰 |

| 15 |

41 |

31.7 |

24 |

14 |

40 |

16 |

7.8 |

20×3.0 |

|

| 20 |

41 |

41.3 |

32 |

20 |

45 |

19 |

8.8 |

25×4.0 |

|

| 25 |

41 |

47.6 |

38 |

28 |

50 |

24 |

9.5 |

30×5.0 |

|

| 32 |

41 |

54.0 |

44 |

33 |

55 |

28 |

10.3 |

38×6.0 |

|

| 40 |

41 |

63.5 |

51 |

42 |

60 |

30 |

12.6 |

48×8.0 |

|

| 50 |

41 |

79.4 |

67 |

52 |

70 |

37 |

12.6 |

60×10.0 |

|

| 65 |

32 |

108 |

89 |

65 |

75 |

45 |

20.5 |

76×12.5 |

|

| 80 |

32 |

132 |

114 |

81 |

80 |

55 |

25.5 |

89×14.2 |

|

|

|

标记示例:

公称通径 40mm, A型6000PSI系列法兰:

法兰 A 40-6 JB/ZQ

4187-97

(标准的附录A)

与法兰连接的平面的尺寸和要求

A1与分体式高压法兰连接的平面要求和相关尺寸见图A1和表1。

|

|

|

"M"表示公制螺纹连接的字符。如设备在国内使用,可能不标志"M"字符:如果出口设备,则应标记"M",该字符采用钢印打记,其位置必须放在O型密封圈区域之外。

|

表1

| 公称能径DN |

工作压力MPa |

d30

-1.5 |

j |

c

± |

r |

u

±0.25 |

v

±0.25 |

w±0.25 |

x

min |

y |

z |

d1 |

L1 |

AA |

BB |

CC |

|

3000PSI法兰 |

| 15 |

21 |

12.7 |

54 |

38.1 |

8 |

19.05 |

8.75 |

17.5 |

33 |

46 |

23 |

M8×1.25 |

12.5 |

56 |

52 |

49 |

| 20 |

21 |

19.1 |

65 |

47.6 |

9 |

23.8 |

11.15 |

22.3 |

41 |

52 |

26 |

10×1.5 |

16.5 |

68 |

61 |

55 |

| 25 |

21 |

25.4 |

70 |

52.4 |

9 |

26.2 |

13.1 |

26.2 |

48 |

59 |

29 |

10×1.5 |

16.5 |

72 |

67 |

61 |

| 32 |

21 |

31.8 |

79 |

58.7 |

10 |

29.35 |

15.1 |

30.2 |

54 |

73 |

37 |

10×1.5 |

19.5 |

82 |

78 |

75 |

| 40 |

21 |

38.1 |

94 |

69.9 |

12 |

34.95 |

17.85 |

35.7 |

64 |

83 |

41 |

12×1.75 |

19.5 |

96 |

90 |

85 |

| 50 |

21 |

50.8 |

102 |

77.8 |

12 |

38.9 |

21.45 |

42.9 |

76 |

97 |

49 |

12×1.75 |

19.5 |

104 |

102 |

99 |

| 65 |

17.5 |

63.5 |

114 |

88.9 |

13 |

44.45 |

25.4 |

50.8 |

89 |

109 |

54 |

12×1.75 |

21.5 |

117 |

114 |

111 |

| 80 |

14 |

76.2 |

135 |

106.4 |

14 |

53.2 |

30.95 |

61.9 |

106 |

131 |

66 |

16×2 |

24.5 |

137 |

136 |

133 |

| 100 |

3.5 |

101.6 |

162 |

130.2 |

16 |

65.1 |

38.9 |

77.8 |

132 |

152 |

76 |

16×2 |

26.5 |

165 |

160 |

155 |

| 125 |

3.5 |

127 |

184 |

152.4 |

16 |

76.2 |

46.05 |

92.1 |

151 |

181 |

90 |

16×2 |

27.5 |

186 |

185 |

183 |

|

6000PSI法兰 |

| 15 |

41 |

12.7 |

56 |

40.5 |

8 |

20.25 |

9.1 |

18.2 |

38 |

48 |

24 |

8×1.25 |

14.5 |

59 |

56 |

53 |

| 20 |

41 |

19.1 |

71 |

50.8 |

10 |

25.4 |

11.9 |

23.8 |

48 |

60 |

30 |

10×1.5 |

16.5 |

75 |

70 |

66 |

| 25 |

41 |

25.4 |

81 |

57.2 |

12 |

28.6 |

13.9 |

27.8 |

54 |

70 |

35 |

12×1.75 |

16.5 |

84 |

80 |

75 |

| 32 |

41 |

31.8 |

95 |

66.6 |

14 |

33.3 |

15.9 |

31.8 |

60 |

78 |

39 |

14×2 |

18.5 |

99 |

90 |

83 |

| 40 |

41 |

38.1 |

113 |

79.3 |

17 |

39.65 |

18.25 |

36.5 |

70 |

95 |

48 |

16×2 |

20.5 |

116 |

108 |

101 |

| 50 |

41 |

50.8 |

133 |

96.8 |

18 |

48.4 |

22.25 |

44.5 |

86 |

114 |

57 |

20×2.5 |

23.5 |

137 |

128 |

120 |

| 65 |

32 |

63.5 |

175 |

123.8 |

26 |

61.9 |

29.35 |

58.7 |

115 |

150 |

75 |

24×3 |

35.5 |

178 |

167 |

156 |

| 80 |

32 |

76.2 |

215 |

152.4 |

31 |

76.2 |

35.7 |

71.4 |

139 |

178 |

89 |

30×3.5 |

45.5 |

219 |

200 |

184 |

|

|